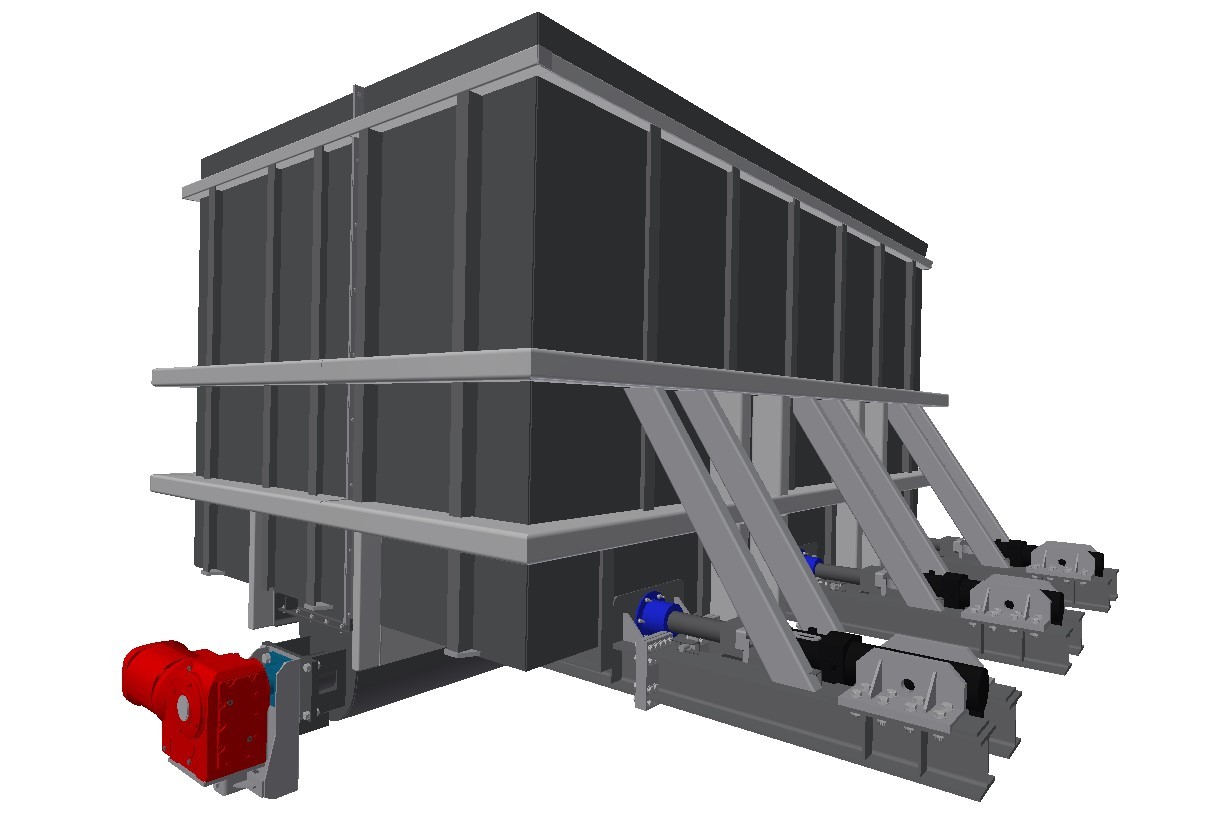

Push floor generally consists of a series of pusher frames or ladders located on bearing beams. These beams travel through the machine and terminate at one end where a cross beam is located and onto which the hydraulic cylinders are fixed. These cylinders drive the pushers forwards and backwards over the floor, which can either be made in steel plate or concrete depending on the machine and material type. At the discharge end of the PUSH FLOOR an adjustable gate is positioned beneath which the stored material is pushed or pulled by the pusher frames. The material then falls into a fall chute and discharge screw conveyor, which can be at either end of the machine.

The conveyor is maintained full at all times by the action of the pushers, which are stopped automatically by a sensor when the screw is full up. The screw will therefore always only see loose material, which has been delivered to it by the pushers and will therefore always meter accurately at fixed or variable rates.

For some special applications where the material is shredded or fibrous, a levelling screw to assist in the even discharge of the product. Alternatively, the pushers can perform the necessary metering function with a variable speed (flow) hydraulic power pack if required.

This is generally the case with material containing large lumps, which make it unsuitable for transport in a screw conveyor. The machine will then deliver directly onto a belt, chain or PUSH FLOOR conveyor.

The flat bottom floor of a bunker allows to use the Push Floor in a number of different configurations to suit the client’s requirement.

Application

The Push Floor discharger is especially suitable for handling heavy, wet and generally non-free flowing bulk solid materials.

List of Materials handled

Aluminium hydrate, Ammoniumnitrate, Bark with slabwood, Biowaste, Cardboard waste, Carnallite, Cellulose residue, Chemical gypsum, FGD, Chicken litter, Chopped straw, Coal pond slurry, Contaminated soil, De-inked paper sludge, Dry particle board, Flakes, Dry sawdust, Fertiliser, Fibrous waste, Garden waste, Hacked woodships, Hospital waste, Joinery waste, Metal dust, Metal foil waste, Mycel, Natural gypsum, North sea silt, Nylon flock, Paper pulp waste, Peat, Petcoke, Phosphate, Pole shavings, Polyester flock, Raw animal feed, Refuse derived fuel, Refuse derived fuel flock, Sander dust, Macerated sewage screenings, Sewage sludge cake, Shredded refuse, Shredded refuse, Tyres, Slag from steelworks, Soil fines, Soya dust, Waste fibres, Wet clay fines, Wet particle board flakes, Wet sawdust, Wet tree bark.

Get in touch