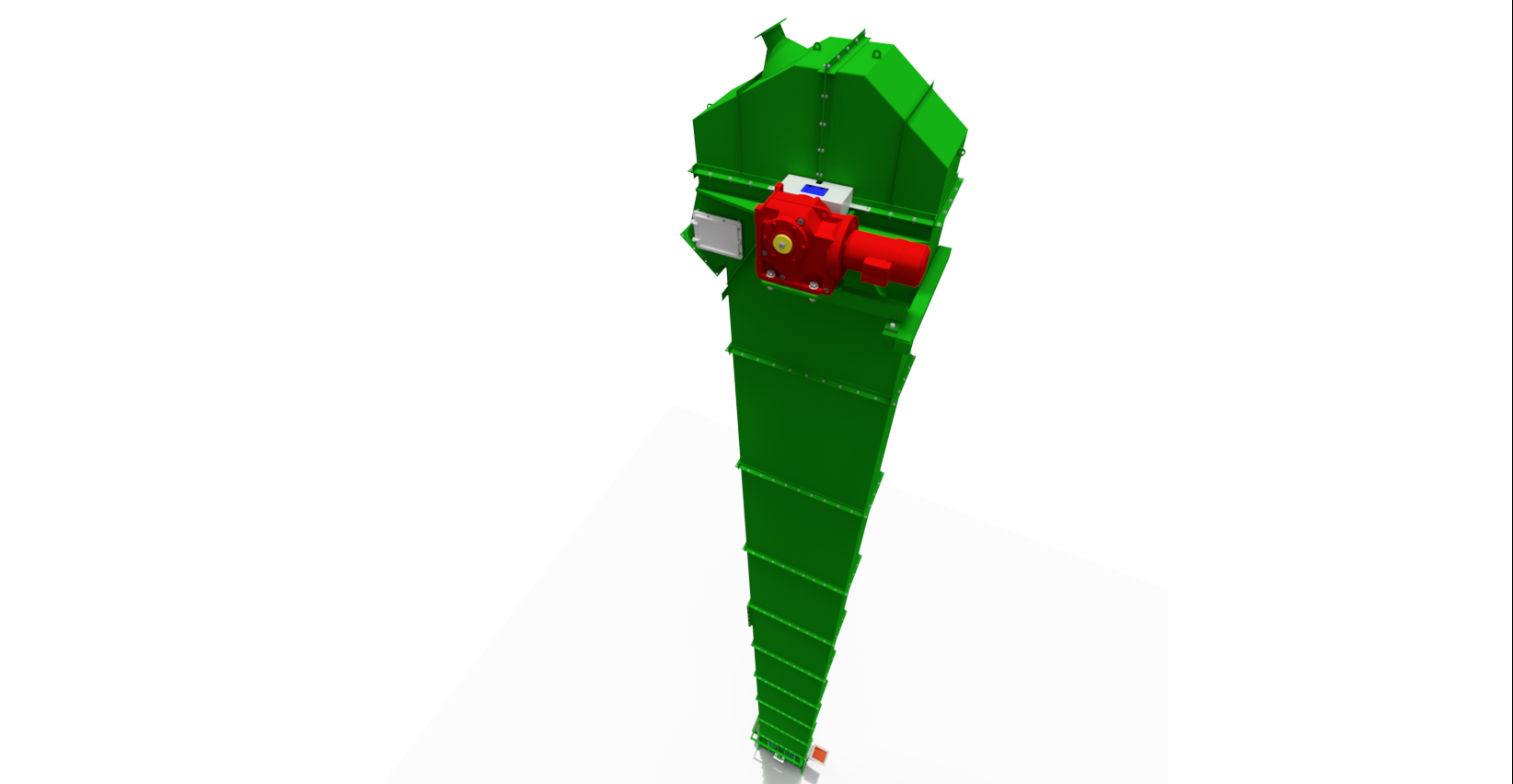

Tratec Solutions bucket elevators are available in standard sizes from 5 to 300 m3/hr, using either belt and bucket or chain and bucket technology. The elevator is self-supporting and is built up of robustly designed head and boot casings with intermediate trunking. The elevator is supplied complete with drive and anti-run back device. A head platform will be provided for use when servicing the drive, with access by cat ladder, stair tower (as pictured) or other plant platform.

Belt and Bucket option:

The standard rubber belt is multi layer fiber reinforced with plain rubber surfaces two mm thick each side, selected for the particular application. The tension pulley may be located either at the top or the bottom part of the elevator. The drums are designed to self-align the belt, and the bottom drum is self-cleaning, using a special cage type construction.

Chain and Bucket option:

Tratec Solutions select the best proprietary chain and bucket systems available, usually with TS shackles. These elevators are optimized with various chain wheel options and can be supplied with inboard sacrificial bearings for a totally dust tight boot.

Other options:

- Service platforms,

- Auxiliary maintenance slow speed drive,

- Choice of rotation monitors,

- Overfilling level sensor at outlet,

- Client's preferred bearings.

Advantages:

- Minimum factory space

- Low power consumption

- Low maintenance expenses

- Freedom from jamming.

Get in touch