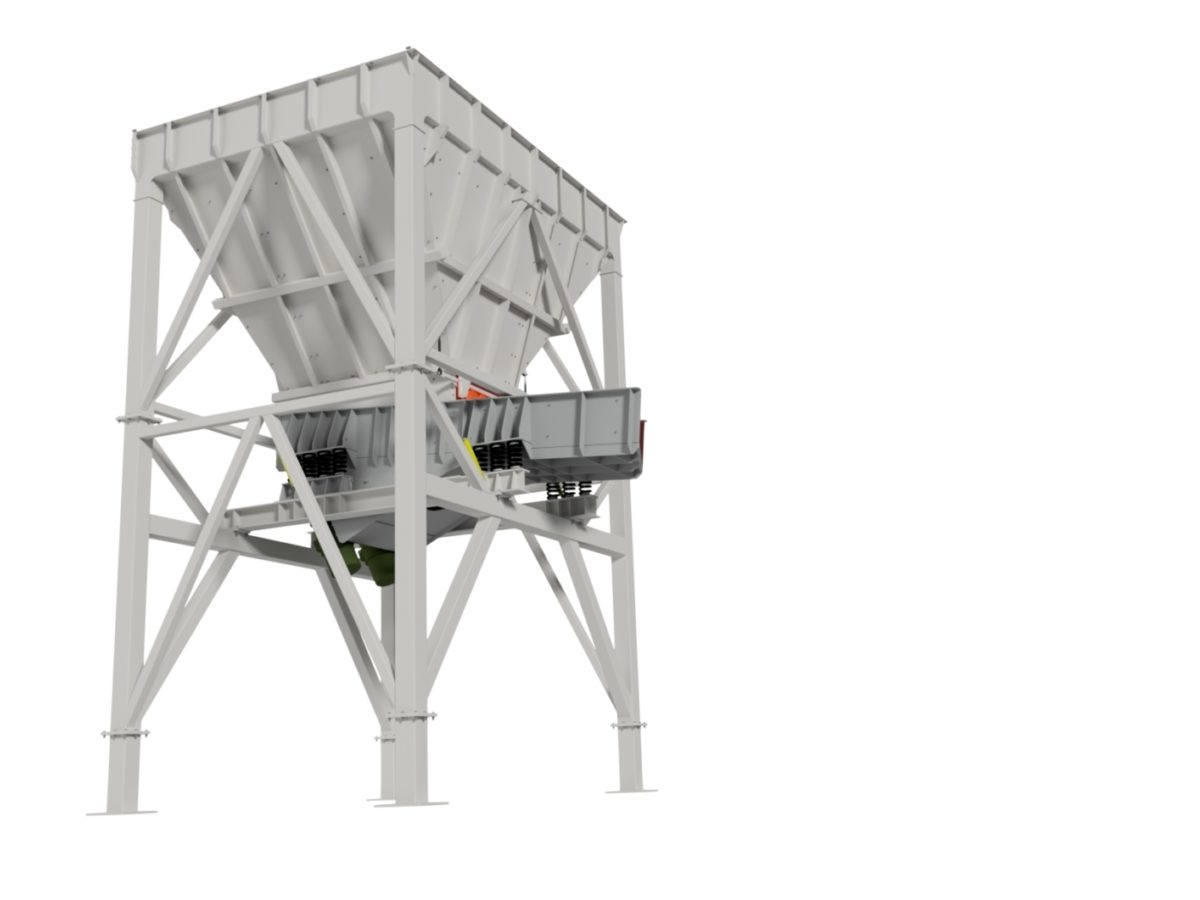

Tratec Solutions vibration conveyors and feeders, using several decades of experience and supplied variety of the vibration machines, can design and supply machines tailored to suit specific customers requirements. To supply optimal solutions

The vibration conveyors / feeders can handle hot or cold material with small or large particle size, and can easily be sealed off to avoid dust.

They are normally used for horizontal transportation, but can also be inclined or declined.

Tratec Solutions Standard delivery range – Economy and efficiency Feeders for most applications.

Benefits:

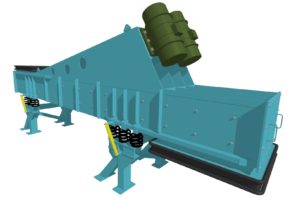

- Wide range of sizes and capacities enables the possibility of best possible interface towards existing/surrounding equipment.

- Standard equipped with mounting bracket for shock absorber. Shock absorber reduces the horizontal movement of the machine during start and stop.

- Small range of standardized wear-plates covering several machine types enables less tied up capital in spare part stock.

- The conveyor is mounted on coil springs which transmit low vibration to the foundation, which in turn leads to lower maintenance costs.

- Easily scalable range, to suit most applications.

Tratec Solutions standard range of vibration conveyors and feeders is based on several decades of experience. We have, through the “Agdermaskin” branch, been delivering over 1800 vibrating feeders and screens since the mid 1960’s, when we started our machine-register.

To supply optimal solutions, the vibration feeders and conveyors can handle both hot or cold material with small or large particle size and can easily be sealed off to avoid dust.

The machines are equipped with 2 unbalance motors which produce a linear vibration. To adjust the capacity, the stroke length is adjustable by tuning the unbalance weights. In addition, the capacity can be controlled during operation, when connected to a frequency converter. The frequency converter also help to minimize uncontrolled vibration forces during start/stop of the machine.

The conveyors / feeders are suspended from spiral springs to transfer as little vibration as possible to its foundation.

- See our standard vibration feeders VRF.

- See our standard vibration feeders VTF-RB.

- See our standard vibration conveyor VTC.

- See our standard vibration feeders VTF.

Tratec Solutions custom delivery.

Tratec Solutions can also design, and supply machines tailored to suit specific customer requirements. Se selection of alternative shapes and configurations in this link.

Vibration feeders

The customer defines the task – Tratec Solutions optimizes!

Get in touch